Silver Nanowires, Nanorings, Nanoparticles & Nanoinks are now available for shipping world wide.

About Us

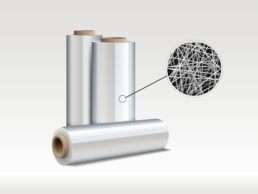

Transparent Conductive Films

Film Sheet Size: 24 cm x 30 cm

This product is transparent conductive film. PET was used as a transparent substrate. The film shows high transparency >90%, and low haze <1% at Sheer resistance of 100 ohm/sq.

The main applications of (transparent) conductive films are:

- Touch screens (smart-watches, mobile phones, tablets, car panels)

- Flexible displays (TVs, smart buildings)

- Smart Glass (PDLC, Electrochromic, photochromic, thermochromic…)

- Transparent Heaters

- Flexible Solar Cells

- Transparent Solar cells

- Flexible High-intensity LEDs and OLED (organic light emitting diode)

UV Curable Conductive Ink for Screen Printing (Conductivity (S/m): > 10^4)

High viscous Conductive Ink

UV-Curable Silver Conductive Inks

Conductive fillers: Silver Nanoparticles

Recommend process: Screen Printing

This product is ready-to-use UV-Curable Conductive Ink (free of solvents), for screen printing that can be used to print conductive lines. The printed lines can be cured by UV light (LED) in a few seconds. The substrate that can be used for these inks includes glass, PET, PMMA, PC, PI, PEI, etc.

Silver Nanowires (Length: 20 um | Diameter: 20-25 nm)

Silver Nanowires in water

Average Length: 20 um

Diameter: 20-25 nm

Silver Nanowire (NW2020) consider as an ultra-thin diameter with an aspect ratio >1000. It can be used as conductive filler to formulate conductive ink to fabricate transparent conductive films with low haze value (Haze of Substrate +0,35%) and considered as best alternative for Indium tin oxide (ITO) Film with high flexibility.

Silver Nanowires (Length: 5 um | Diameter: 20 nm)

Silver Nanowires in water

Average Length: 5 um

Diameter: 20-25 nm

Silver Nanowire (NW2005) consider as an ultra-thin diameter and short length. This product is mainly used as a conductive filler to formulate conductive inks mainly for dispensing and ink-jet printing. By having short NWs, fabricating more stable low viscous inks that are normally used with these printing techniques is easier.

Water-Based Conductive Ink (Conductivity (S/m): > 10^5)

Water-based Conductive Inks to print Transparent line/area with Screen Printing (Conductivity (S/m): > 10^5)

- High viscous Conductive Ink

- Water Based Silver Conductive Inks

- Conductive fillers: Silver Nanowire

- Recommend process: Screen Printing

This product is ready-to-use Water based Conductive Ink for screen printing that can be used to print transparent lines and/or fabricate Transparent Conductive Film. The substrate that can be used for these inks includes glass, PET, PMMA, PC, PI, PEI, etc.

Water Based Conductive Ink for Dispensing

Low viscous Water Based Silver Conductive Inks

Ink Amount: 100 grams

Conductive fillers: Silver Nanowire

Recommend process: Dispensing methods

This product is water-based and ready-to-use ink that can be applied with dispensing methods to print conductive lines and zones. Meantime, it can be used as inks in conductive pens to repair damaged circuits.

Water-based Conductive Inks for Slot-die Coating

Low viscous Conductive Ink

Quantity: 1000 grams

Type: Water Based Silver Conductive Inks

Conductive fillers: Silver Nanowire

Recommend process: Slot-die, Mayer rod, Doctor Blade, Micro-gravure and Roll to Roll coating technologies, etc.

This product is ready-to-use Water based Conductive Ink to fabricate low haze and highly Transparent Conductive Film. The substrate that can be used for these inks includes glass, PET, PMMA, PC, PI, PEI, etc.

Water-based Conductive Inks (Conductivity (S/m): > 10^6)

Water-based Conductive Inks to print Semi-transparent line/area with Screen Printing (Conductivity (S/m): > 106)

High viscous Conductive Ink

Water Based Silver Conductive Inks

Conductive fillers: Silver Nanowire

Recommend process: Screen Printing

This product is ready-to-use Water based Conductive Ink for screen printing that can be used to print Semi-transparent lines and/or fabricate Semi-Transparent Conductive Film. The substrate that can be used for these inks includes glass, PET, PMMA, PC, PI, PEI, etc.

This product can be used to fabricate Transparent Heaters.